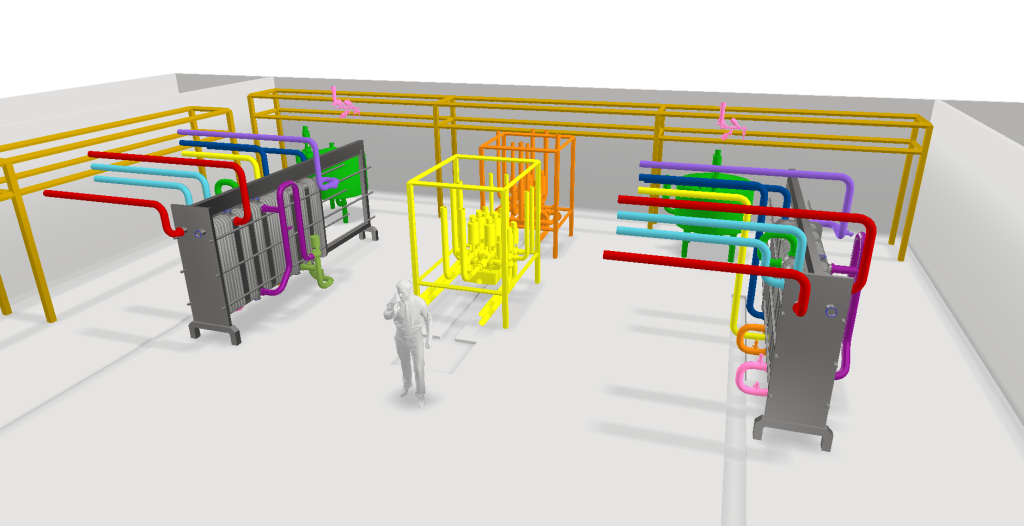

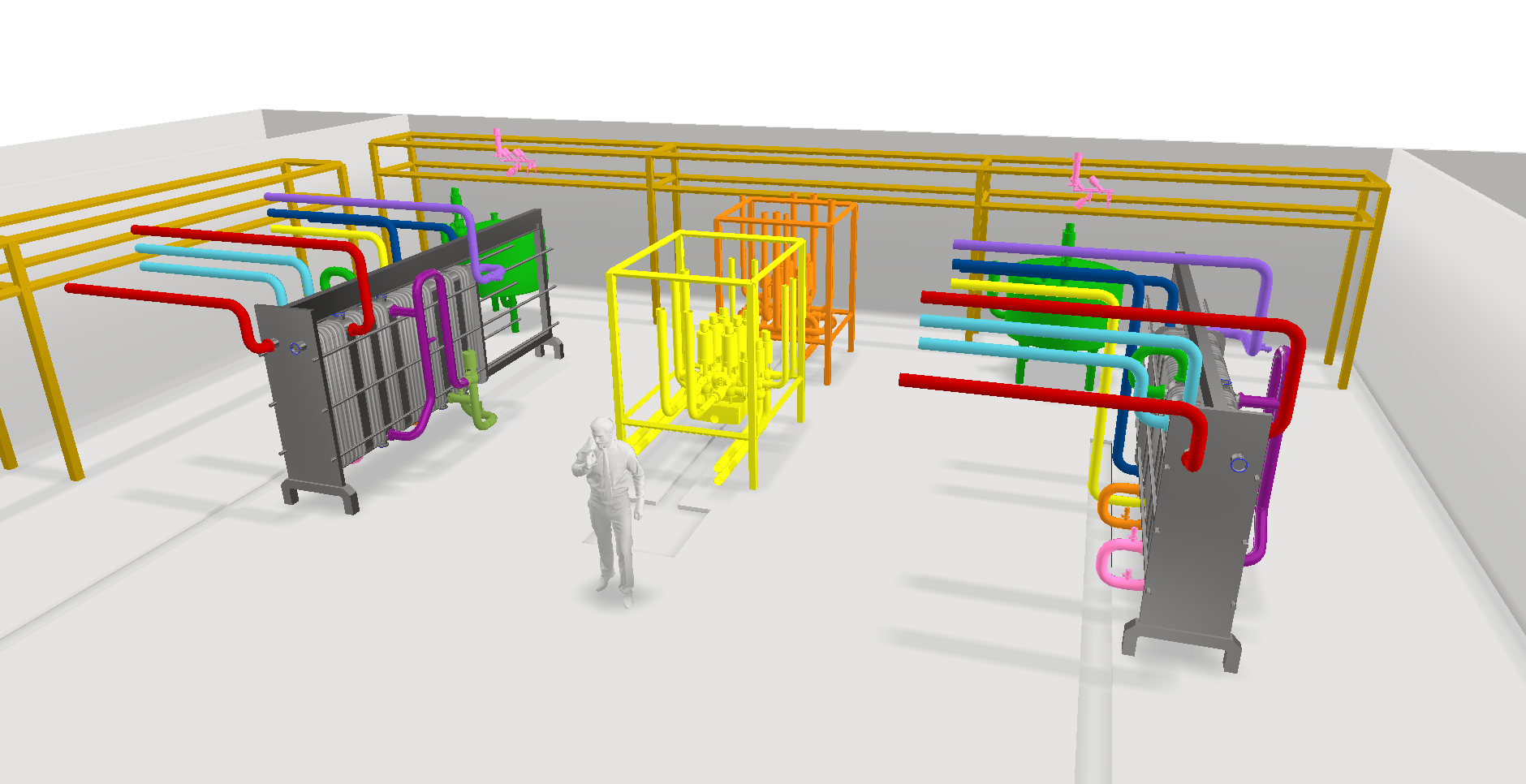

Sycamore Process Engineering is pleased to announce that it has been awarded a contract to deliver the design, build, and installation of a new Duplex Pasteurisation system for a major cheese maker in Devon. The works will consist of the design, build and installation of two 66,000 l/h state-of-the-art, energy efficient cheese milk pasteurisers, complete with hot water generation sets, raw and finished milk routing manifolds as well-as an upgrade to the raw milk intake area to streamline delivery to the new plant.

Sycamore Process Engineering was successful following a lengthy tender process and the project is now estimated to be completed in July 2021. The new milk processing equipment will come to life in the heart of the creamery and connect to a Cheese Vat room which was also completed by Sycamore Process Engineering in late 2019.

The Duplex Pasteuriser line will mean increased capacity and flexibility of cheese production on the site, as by having two pasteurisers, they are no longer limited by a single run time per heat exchanger before it needs to be cleaned. Duplex gives the ability to run for 24 hours a day if required and allows for a seamless changeover between pasteurisers, enabling one to be in production and one being cleaned and so on.

Paul Manning, Project Director at Sycamore comments: “We’re thrilled to have won the tender for this project and excited to act as an extension of the team for this major producer of dairy products. We’re currently working on the P&ID and with the civils team so we can ensure our designs fit exactly to the different elements of the room, not just to be aesthetically pleasing, but being involved this early means we can achieve additional efficiencies in the use of energy, light, drainage and ventilation. We can’t wait to get stuck in.”

*Image shows early concept model