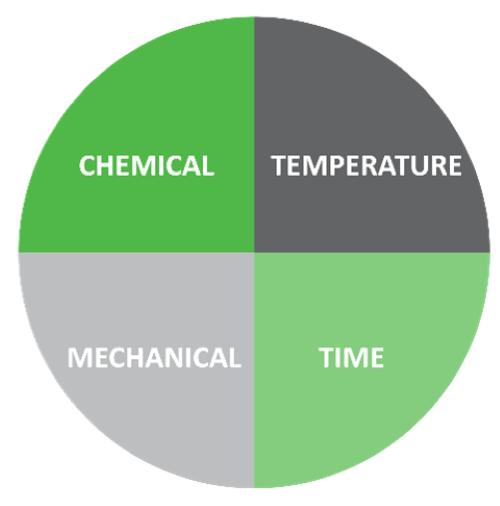

Since Clean in Place (CIP) was developed in the 1950’s it has been used across many industries including dairy, food, and beverage, and at times, gets overlooked as a fundamental part of end-to-end process solutions. To the untrained eye, CIP on the surface is something that is very simple, a process of cleaning production lines/objects without the need for dismantling. The key fundamentals of CIP are derived from the four key parameters of Sinner’s Circle: mechanical force, temperature, time, and chemical action.

CIP systems have been designed and installed over the years by many reputable companies and have performed well, giving the desired repeatable clean, however, in some cases, not much thought necessarily went into the energy efficiency or sustainability of the plant. In short, process engineers did what they needed to do to achieve and ensure a sufficiently clean and focused purely on the final required result.

Well, times have changed with a shift worldwide now focusing on sustainability, CIP needs to be at the forefront of everyone’s mind as one of the key processes that are addressed in this new environmentally friendly world.

The importance of making the right design selections to satisfy the above key parameters is essential in providing an energy-efficient solution. The availability of performance and simulation data has significantly improved for chemical and mechanical products which supports this and allows for engineering solutions to be optimised to suit its needs, rather than over-engineering and “playing it safe” with aspects of the CIP system such as pump size, heat exchanger selection, processing temperatures, and chemical dosing strengths.

Cutting-edge CIP sets can be designed and installed with all of this in mind without comprising the many CIP standards and codes of practice that retailers and producers require. Selection of appropriate chemicals, the accuracy of dosing, and tight interfaces between the CIP phases complete with process engineering optimisation will all play their part in ensuring producers have the most up-to-date, energy-efficient CIP systems available on the market today.

The CIP set itself is only one part of the puzzle. Its integration within the factory, as a whole, plays an equally significant role in ensuring efficiency and sustainability is maximised. Strong links between the process engineering company designing the CIP system and the end user’s expectations being aligned are paramount for this to be a success.

The environmental impact of cleaning a process vessel for example can be drastically improved by the correct selection of spray head/cleaning devices within the vessel. The selection of a low-flow type unit can provide a dramatic reduction in water consumption when compared with a static style spray ball.

The CIP allocation for each object within a site can provide large increases in production efficiency. An example of this would be the reduction of a CIP cleaning window from 6-hours to 4-hours meaning a product production window increase from 18 hours to 20 hours. By assessing the plant as a whole and giving suitable CIP capacity, the same number of assets (same energy requirement) can be cleaned within a shorter timescale, allowing greater production through a day which ultimately results in a greater product capacity per KWh of energy consumed.

Clean in Place should no longer be seen as simply meeting hygienic standards, but when designed, manufactured, and installed by CIP experts, such as Sycamore Process Engineering with their know-how, can enable your processing facility to remain hygienic, however, be more environmentally friendly with less wastage and downtime, ultimately enabling you to produce a greater daily yield.

Read more on how you could benefit from our CIP systems here.