Hygienic 50,000lph duplex pasteuriser room increases production for Somerset cheesemaker

Sycamore Process Engineering has been a partner of Barbers Farmhouse Cheesemakers for many years. The business has successfully completed hundreds of projects for Barbers over the years of all shapes and sizes, the duplex pasteuriser project however, being one of our favourites.

The duplex pasteuriser system enables us to have longer production runs and the insurance of a second line should there be a problem or a breakdown. It’s helped Barbers increase production and more importantly improve process control

Anthony BarberDirector at Barbers

The new pasteuriser room was purpose built which meant we could go above and beyond in the design phases to ensure all aspects supplied by Sycamore complied with EHEDG (Hygienic Engineering & Design Group) guidelines. This included installing solid section stainless steel framework supports off the main building portal, before the hygienic cladding had been put in place. This also meant the structure now takes up less space within the new pasteuriser room and has fewer exposed supports for a cleaner design and crucially fewer surface areas that would require regular cleaning.

“The duplex pasteuriser system enables us to have longer production runs and the insurance of a second line should there be a problem or a breakdown. It’s help Barbers increase production and more importantly improve process control,” commented Anthony Barber, Director at Barbers.

Barbers have been making farmhouse cheddar cheese for longer than anyone else in the world, and with the demand so high for the quality cheese they needed to be able to increase production and pasteurise continuously. The installation of a new duplex Pasteuriser system meant they could do just that.

Technical

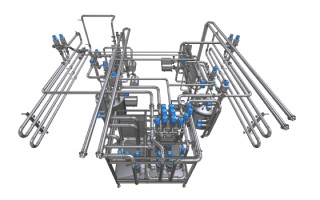

The system was designed by Sycamore and the engineering team on site at Barbers, and consisted of automatic milk routing, a CIP set, duplex pasteurisation complete with stand-alone separation and standardisation systems, automatic starter culture dosing and new starter culture vessels, all powered and controlled by the Barbers onsite automation and electrical team.

Anthony added: “We continue to use Sycamore because we always get a personal service and high standard of workmanship. I wouldn’t hesitate to recommend them for anything that requires stainless fabrication or installation.”

Design and Materials

Some of the equipment and materials we selected can also be found in the pharmaceutical industry because of its ultra-hygienic features, which meant every part we sourced for this project was EHEDG approved. This was a great challenge for our design team as it meant we couldn’t have any flat surfaces or parts with internal cavities, but resulted in an easy to clean, food safe, hygienic and efficient pasteurisation room that both Sycamore and Barbers are very proud of.