Sycamore Process Engineering has joined forces with international food and drink group Princes. The team at Sycamore worked hard throughout the bid process to ensure they were selected as the preferred supplier and were awarded the contract during 2021. Princes are currently in the process of re-engineering their Cardiff centre of excellence to increase the production of fruit juice and drinks. This project is part of the third phase and includes the relocation and upgrades to their pasteurisation lines used for the production of their fruit juices and drinks.

Once the contract was agreed and awarded the project was able to commence, the initial stages of this project included the removal of existing equipment from Princes’ production facility in Manchester and placed into storage at our manufacturing facility in Sparkford, Somerset. As part of the removal stage, we were able to carry out an inspection to ensure the processing equipment that was due to be relocated is in good working order. After we had completed these integrity tests the heat exchangers on the hot water sets that we had removed from their production facility in Manchester were replaced, ensuring Princes were being supplied with reliable equipment and offering the latest efficient designs.

Not only does this project include the relocation of equipment from Manchester to Cardiff, but we will also be upgrading and supplying new processing equipment to ensure Princes gain the most benefits from their investment. The process engineering upgrades that we have been able to offer to the Princes group included a change in the plate pack heat exchanger which will boost the regenerative efficiency to maximise energy recovery.

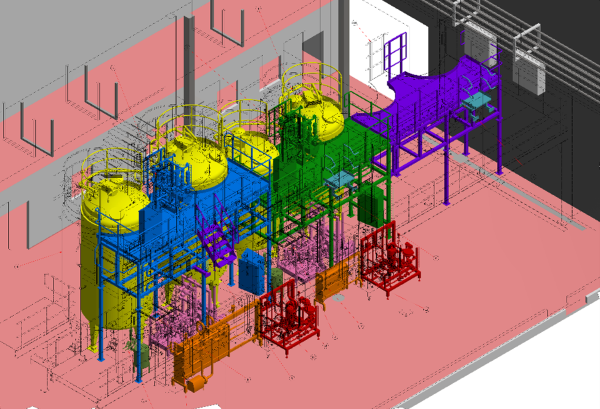

Towards the end of 2021 the manufacturing commenced at our workshop when designs had been finalised, the manufacturing process included our team of engineers constructing the modules and access platform that are due to be installed during the first quarter of 2022. The 1090 UKCA approved access platform was designed alongside Princes to accommodate their expansion plans.

Further collaboration shown by the design team was the four-day HAZOP that one of our Process Designers completed with Princes’ engineering team to verify the safe operation of the plant, as well as the flexible design approach to ensure the Clean In Place requirements and product specifications would be met. Members of our design team were also able to work with our automation partners Au2mate and members of Princes’ automation team on the development of the functional design specification, ensuring Princes were fully satisfied that their requirements had been achieved.

The mechanical layout design consisted of our team focusing on the key process parameters and functionality of the new plant, this also included the new access platform enabling the operator easy service and maintenance of all the associated equipment with the new juice pasteuriser modules.

Whilst still in our manufacturing facility the team were able to test and ensure the prefabricated modules and platforms fitted together to reduce installation and production downtime on site.

As the project continues at pace, the focus now starts to shift to the onsite installation. Our team of installation engineers have arrived on-site and have begun this part of the process, ready to receive the delivery of the processing equipment to be installed at Princes’ Cardiff centre of excellence.

Keep an eye on our social media feeds for updates on how the project continues to develop.

Contact us to discuss your processing requirements and find out how we can help you!